Geo-environmental Consulting & Expert Litigation Support

Tunnels and Karst

MMSD Cross Town Tunnel Phase I and II Grouting

MMSD Cross Town Tunnel Phase I and II Grouting

Directed consolidation and permeation grouting of 12 miles of CSO tunnels (16-32ft dia) constructed in un-lined limestone and dolomite bedrock 200-300 feet deep. The Silurian and Devonian age carbonates with numerous faults, fractures, chert nodules, vugs and solution cavities which presented technical challenges to control groundwater. Implemented various cement and chemical based grouting solutions as required.

MMSD North Shore Tunnel Mapping and Grouting

MMSD Cross Town Tunnel Phase I and II Grouting

Conducted 360 degree geologic mapping of more than 9 miles of 32-ft and 16-ft diameter tunnels. Mapped mineralogy and geology, strike and dip of bedding, faults, fractures, solution cavities, and groundwater infiltration zones. Conducted dye studies to determine groundwater infiltration zones and rates to improve tunnel grouting programs. Mapping work supported the settlement of construction claims valued over $100MM.

Other MMSD Tunnel and Shaft Pre-Grouting

MMSD Tunnel/Shaft Pre-Design Studies and Aquifer Testing

Conducted "pre-grouting" of shafts and tunnels prior to sinking shafts and driving more than 8 miles of tunnel in Milwaukee. Grouting was accomplished with angle drilling to effectively seal fractured bedrock using surface drill rigs or rigs to drill in advance of Tunnel Boring Machines (TBMs). These pre-grouting programs were implemented because of difficulties with grouting after tunnel/shaft construction.

MMSD Tunnel/Shaft Pre-Design Studies and Aquifer Testing

MMSD Tunnel/Shaft Pre-Design Studies and Aquifer Testing

Field geologist responsible for logging more than 2 miles of soil and rock cores along proposed tunnel alignments and drop shaft locations. Also completed thousands of bedrock packer tests to determine proper grouting procedures. Conducted numerous large scale bedrock aquifer pumping tests and dye studies. Installed and operated groundwater systems, groundwater recharge systems, ground freezing systems and MPBX slope indicators.

MBTA Silver Line and Fort Point Channel Tunnel Crossing

MBTA Silver Line and Fort Point Channel Tunnel Crossing

Technical lead, developed environmental investigation to pre-characterize the presence of contaminated soil along the tunnel alignment prior to construction of a new subway tunnel in Boston. Developed Soil Management Plan to comply with the Massachusetts Contingency Plan, which specifies requirements for the assessment and remediation of contaminated sites. The plan helped accelerate the construction and waste management process.

MWRA Metro West Water Supply Tunnel Grouting

MBTA Silver Line and Fort Point Channel Tunnel Crossing

Grouting consultant for the more than 17mile long, 12-14 feet diameter tunnel for Massachusetts Water Resource Authority (MWRA) Metro West Water Supply Tunnel (MWWST) that provides water for most of Greater Boston. The grouting programs involved pre-grouting, post-TBM grouting, cementitious grouting and chemical grouting to seal this 200 feet deep rock tunnel. Tunnel was constructed to provide a contingency water supply line to a 19th century aqueduct.

Solvent Chemical Superfund Site Karst Grout Curtain Design

Developed dolomite bedrock grout curtain design for a groundwater containment barrier remedy at this Superfund Site that produced chlorobenzene. DNAPL is present in multiple zones including the Silurian Age Lockport Dolomite formation with karst features. Barrier was developed to separate comingled plumes from adjacent facilities.

Karst Sink Hole Remediation RCRA Cleanup Site in Puerto Rico

Remediation engineer. Developed and conducted Soil Vapor Extraction (SVE) pilot test and SVE design to address chlorinated solvent NAPL present beneath a chemical above ground storage tank (AST) Tank Farm situated above a filled karst "sink hole". The releases of VOCs exceeded explosive limits and required gaseous nitrogen drilling.

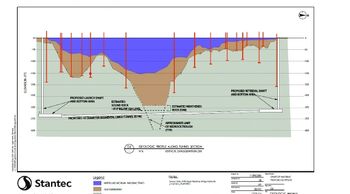

Enbridge Line 5 Replacement Tunnel Pipeline Permit Review

Enbridge Line 5 Replacement Tunnel Pipeline Permit Review

Technical Advisor to the Michigan Environmental Council. Provided tunneling expertise and written technical comments to ELGE/USACE on permit applications for this $500MM project. Identified and documented numerous technical fatal flaws and deficiencies, provided media interviews and led a call with EGLE Director.